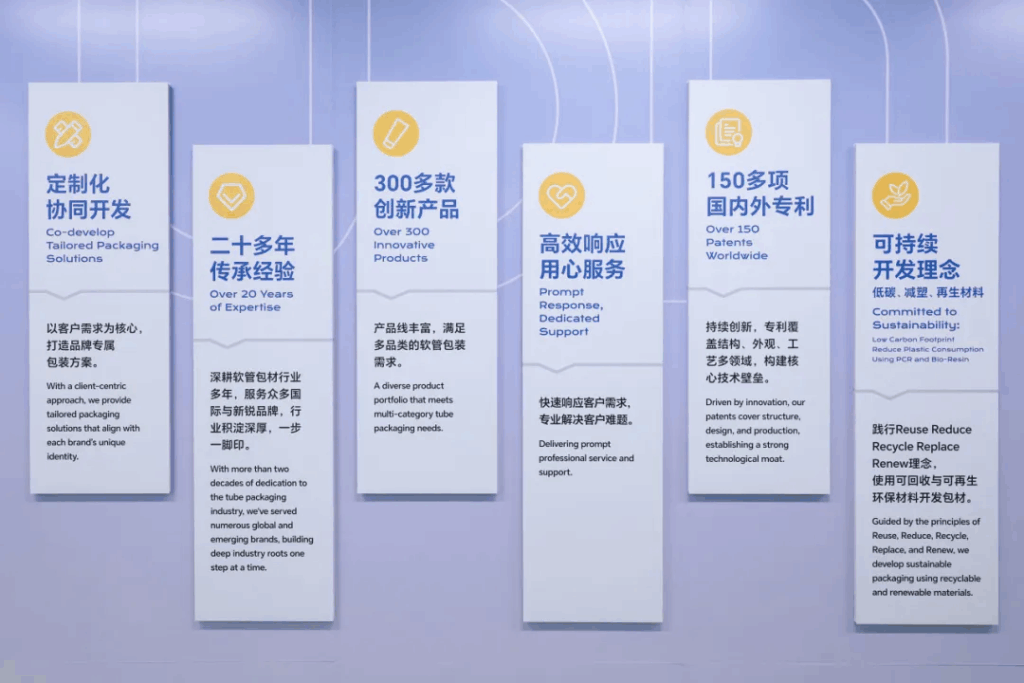

In the beauty industry, speed defines survival. The faster a brand can deliver high-quality products, the stronger its competitive edge and long-term partnerships.

For UDN, the answer lies in APIS, a lean manufacturing system that connects every stage of production, from pre-order planning and in-process execution to quality assurance, post-production reviews, and performance feedback.

Since its implementation in 2022, APIS has redefined how UDN operates. With three years of continuous refinement and large-scale production trials involving millions of tubes, APIS has become UDN’s “Engine of Efficiency.”

Speed: Agile Response and Shorter Cycles

The biggest strength of APIS lies in its proactive planning. UDN transformed traditional segmented processes into a “one-flow operation” — integrating tubing, printing, and assembly into a continuous production line. This drastically reduces waiting time between semi-finished stages and ensures smoother transitions across the workflow.

Case Highlights:

- Working hours per thousand tubes reduced by up to 65%.

- For the same product, the production and delivery cycle was shortened from one month to just three days, boosting efficiency by 900%.

Stability: Automation and Standardization for Quality Assurance

Agility must be matched with stability. UDN continues to invest heavily in automation and standardization, minimizing large-scale production inconsistencies and advancing its “zero-defect” philosophy — no defective products made, accepted, or passed on.

Key Improvements:

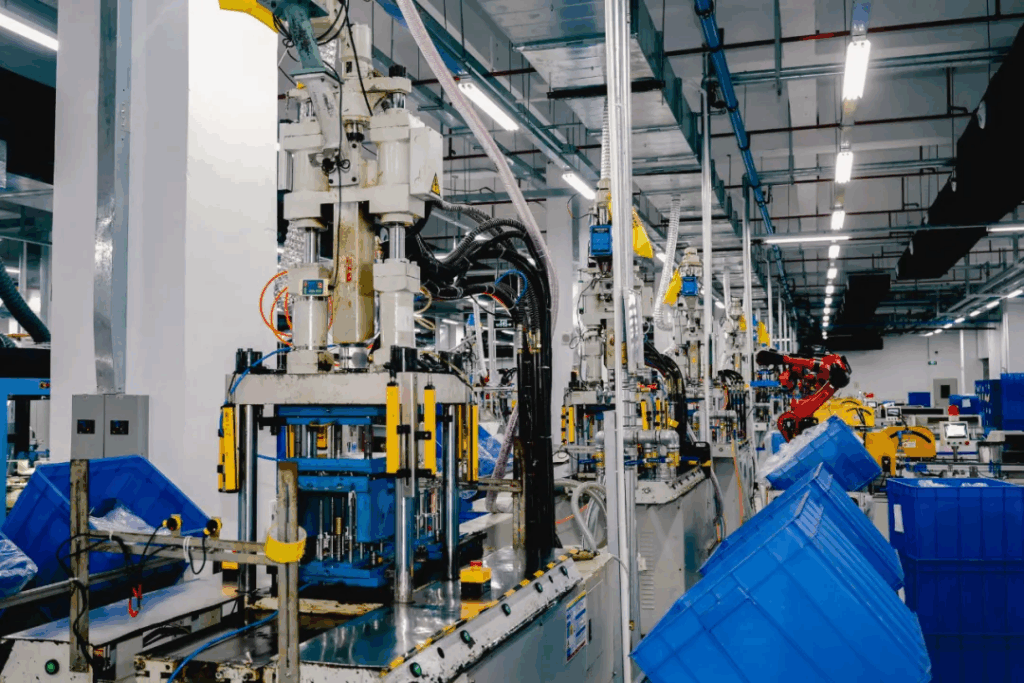

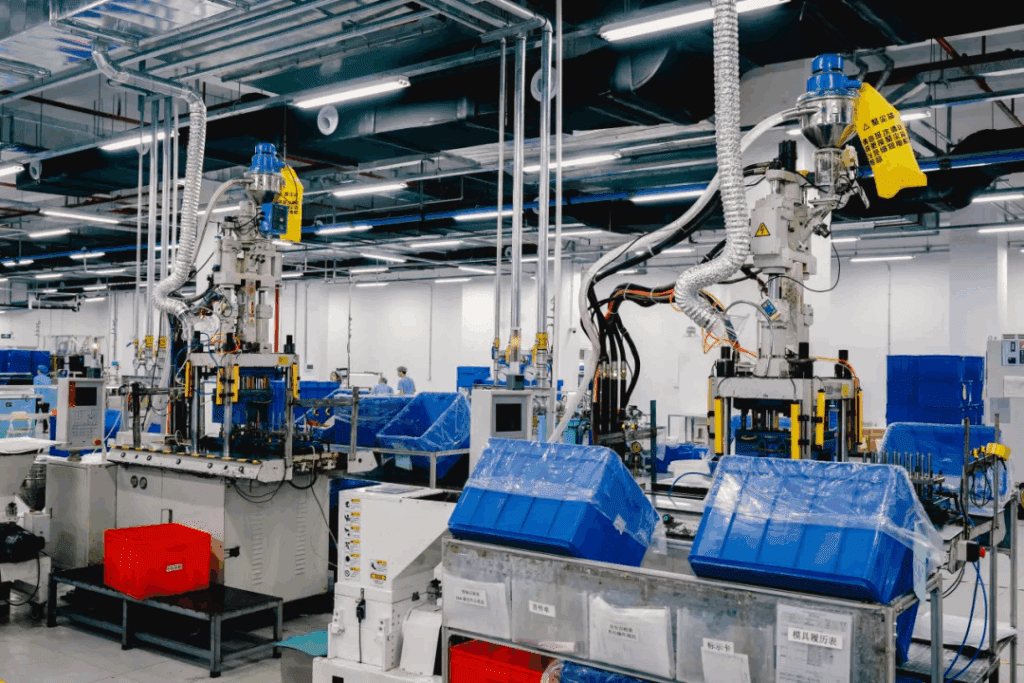

- Installation of new injection molding machines, capping machines, and robotic arms, expanding capacity to tens of millions of units per month.

- Nearly complete upgrade to servo equipment, moving toward digital intelligent manufacturing.

- Automation of critical processes such as injection molding and capping, resulting in multi-fold efficiency gains.

- Real-time, minute-by-minute production tracking during quality control improved the first-pass yield from 40% to 90%.

Sustainability: Institutionalized Systems for Long-Term Trust

APIS is not a one-time reform, but a continuous, institutionalized evolution of how UDN works.

Key Mechanisms Driving Long-Term Success:

- Dedicated APIS Taskforce: Implements growth mechanisms, plans daily production flows, sets specific goals for each stage, and conducts regular reviews.

- Company-Wide Participation: Over 80% of improvement proposals come from frontline operators, embedding a culture of efficiency and innovation across all teams.

- Performance Incentive System: Tracks production efficiency at the process level, ensuring transparent performance rewards. To date, APIS has generated over RMB 1.5 million in additional bonuses, reinvesting 100% of cost savings into team incentives.

- Data Asset Accumulation: Builds a robust, reusable “Best Practice Database” from frontline data to guide decision-making with precision.

Efficiency that Empowers Every Launch

At UDN, product launch speed and quality performance are always at the heart of our mission. The value of APIS goes beyond efficiency — it ensures a reliable, predictable production experience for every client.

We extend our sincere gratitude to our production management teams and all colleagues who have contributed to this transformation. Through their dedication and continuous improvement, they safeguard the success of every product we help bring to life.